- Product Detail

- Product Tags

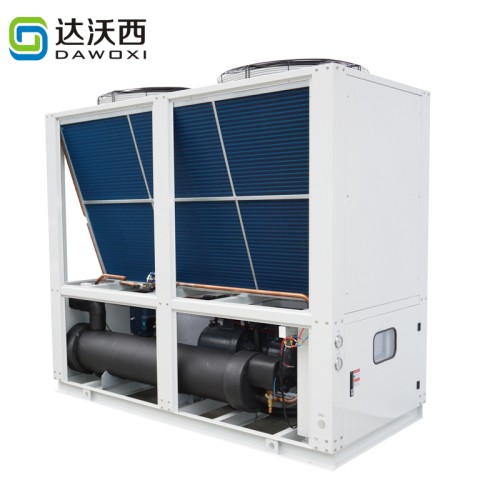

The 1℃ low-temperature chiller system developed by Davosi Organization Company does not require any antifreeze medium when the outlet water temperature is 1℃. Compared with the traditional chiller , which needs to add antifreeze when the temperature is below 5℃, the application scenario is greatly improved. It is widely used in agricultural cleaning links such as fruit and vegetable cleaning, poultry cleaning, and seafood cleaning. Some special scenarios that need to be applied to 1 ℃ are as follows: For these dairy processors, everyone has strict requirements for refrigeration equipment and facilities: high requirements for temperature control, high requirements for unit stability, high requirements for heat exchange medium, and high standards for the intelligence of the machine room.

1 °C Constant Temperature Cold Water System Solution

The chilled water system unit sends qualified chilled water into the water supply tank, which is then pumped to the terminal scene for use through an external circulation pump , and then returned to the unit through the return water tank to complete the cycle. The chilled water supply tank and return water tank are set up to weaken the impact of the terminal load mutation on the refrigeration unit and play a buffering and protective role for the water tank. The chilled water system uses a direct connection between the pump and the machine to optimize and reduce the pipeline resistance.

Technical features:

1. Multiple refrigeration forms

It includes process ice water system, cooling water system, process cooling water system and process tower system.

2. Fine-grained control

Centralized management and control of the cold source room is achieved, and unmanned energy stations, semi-automatic energy-saving control, and fully automatic energy-saving control are realized; active and precise adaptive control technology is adopted, based on accurate control of 0.5℃, to achieve precise adaptation between the automatic control system and the host.

3. Water temperature fluctuations are stable

To ensure system stability, the outlet water temperature of process ice water is always lower than 2.0℃, the temperature in the process ice water supply tank is always lower than 1.5℃, and the outlet water temperature of a single machine is always lower than 1.0℃. At the same time, an instant machine shutdown function is provided to provide a reliable process cooling source guarantee for the workshop.

4. Mechatronics modularization

To achieve unmanned management, various components, including the unit, water pump, water tank, cooling tower, power distribution, and monitoring, can be integrated into a single system, resulting in high integration of refrigeration, power supply, and management components. This integration greatly reduces the space required in the machine room. The modules are flexibly assembled, the overall layout structure is simple and compact, the construction and installation are convenient, and it is easy to disassemble and transport, which greatly shortens the on-site construction and commissioning cycle, realizes the factory prefabrication of the refrigeration room, and brings more economic benefits to the owner.