- Product Detail

- Product Tags

The Thermal Shock Tester is suitable for electronic and electrical components, automation components, communication components, auto parts, metals, chemical materials, plastics and other industries, defense industry, military industry, BGA substrate, electronic chips, semiconductor ceramics and polymer materials. It tests the chemical changes or physical damage of materials to repeated thermal expansion and contraction of high and low temperatures, and can confirm the quality of products. From IC to heavy machinery components, it is an ideal testing tool. The hot and cold shock tester is used to test the degree to which material structures or composite materials can withstand continuous environments of extremely high and low temperature.

Components of Dawoxi Thermal Shock Tester

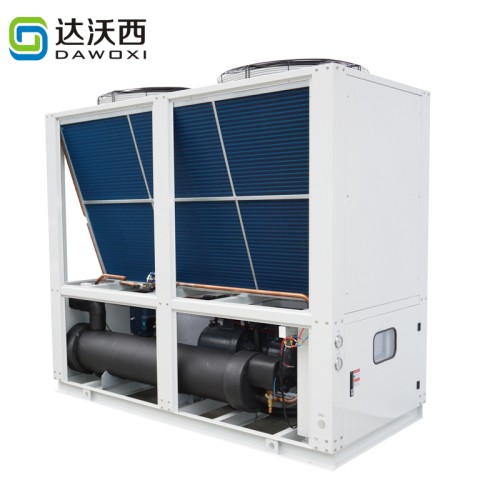

The complete system includes a compressor refrigeration unit, a heating system, a water circulation system, sensors, control devices and auxiliary devices.

1.Refrigeration compressor unit: The refrigeration compressor unit of this system is composed of a compressor, an evaporator, a condenser and corresponding accessories. The refrigeration system provides a constant cold source for the entire equipment. The temperature sensor in the refrigeration box senses the temperature changes in the refrigeration box and uploads them to the temperature controller. The temperature controller controls and adjusts the output cooling capacity of the compressor so that the temperature of the refrigeration box is always controlled within the set temperature range. The temperature value can also be set by the host computer or manually.

2. Circulating liquid tank: The circulating liquid tank is made of stainless steel and consists of a temperature sensor, a heater, etc. The circulating liquid tank detects changes inside through the temperature sensor and uploads the information to the temperature controller, which controls the temperature of the liquid tank by controlling the duty ratio of the cooling solenoid valve and the bypass solenoid valve. The liquid tank is connected to the DUT through an external circulating coolant pump to provide the DUT with cooling media at various temperatures.

3. Circulating coolant pump: The circulating coolant pump is a high-temperature pump. A flow sensor and a pressure sensor are installed at the outlet of the circulating coolant pump to manually control the flow and pressure regulation.

4. Temperature control system: The temperature control system is used to control the temperature of each temperature control point, including the temperature of the refrigerant tank. The temperature control system uses a PT100 armored temperature sensor to collect temperature data, and uses a Siemens PLC controller as a temperature controller to automatically control the temperature of each node in the entire system.

5. Controller: The controller is used for state perception, control of equipment start and stop, control of linkage, control of auxiliary equipment functions, etc., including liquid level sensors etc. The controller realizes the switching of the two working modes.

6. Communication: The system has an analog hybrid communication interface, provides Ethernet and host computer linkage, and realizes remote control.

7. Insulation facilities: This equipment adopts foaming insulation measures and strictly insulates all low-temperature pipelines to ensure energy saving and high efficiency.

Main functions

1. Intelligent control: It uses Siemens PLC intelligent controller, Chinese display, modular operation interface; it can intelligently sense, calculate and adjust various parameters of the equipment. It can also set the temperature of the cold water storage tank. It can manually adjust the output flow and output pressure; it can monitor the return liquid temperature and return liquid pressure.

2. Rapid refrigeration and temperature control: This system adopts direct cooling design. The compressor unit can meet the direct refrigeration within the entire temperature range and obtain a large cooling capacity. At the same time, it can maintain a small amount of water in the circulating water tank during operation and still accurately control the temperature.

The system supports manual and automatic switching of high and low temperature liquid output. Automatic switching supports the editing of time switching logic ( 10 steps) and the setting of the number of cycles.

Note: When switching between hot and cold pipes, there will be a functional conversion time of about 10 seconds. At this time, the system will not transport cold liquid or hot liquid to the outside (complete system switching facilitates system energy saving). If a non-delay system is used, please inform the business in advance.

3. Remote and local control: The system controller has an analog hybrid communication interface, and the controller is equipped with a remote and local conversion switch. It can realize timely conversion between remote and local control.