- Product Detail

- Product Tags

With the upgrading of national industries, there are mandatory requirements for products in all walks of life. Especially in the new energy vehicles, motors, electronic controls, batteries, and electronic aerospace industries, Chinese companies are guided to advance into technological and cutting-edge products. This requires continuous verification of the reliability of various simulation tests on related materials, components, functional units, and systems. Correspondingly, the use of product testing equipment will increase significantly, and at the same time, it has also spawned reforms in testing processes. In order to simulate a wider temperature range, rapid temperature changes, higher temperature stability, and ensure the repeatability of experimental conditions, a higher standard temperature control system is required. The liquid energy temperature function system is a rapid refrigeration testing device produced under this environment.

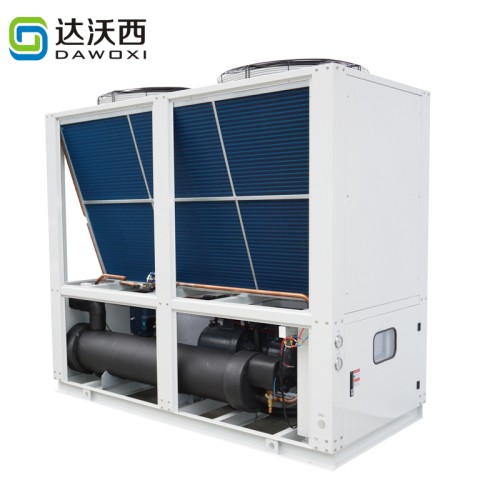

Introduction of Dawoxi high and low temperature liquid cooling system

The liquid cooler is a machine that heats and cools the part under test by passing liquid into it through a liquid energy unit. Since the liquid directly exchanges heat with the part under test, the heat exchange efficiency is high and the temperature of the part under test reaches a fast time, so the liquid energy system can greatly speed up the test cycle. The liquid energy unit has the ability of rapid heat exchange and controllable pressure and flow. It can test the heat exchange capacity of the heat exchange flow channel of the part under test during actual use, the reliability of the system flow channel at different temperatures, and the limit operation capacity of the system flow channel. At the same time, the liquid energy system can be used together with other testing equipment to test the reliability of the actual operating environment of the part under test, avoiding the instability caused by the lack of internal energy testing during the actual operation of the part under test after only external environment and kinetic energy testing in the early stage.

Liquid coolers can perform constant temperature tests, constant pressure tests, constant flow tests, and temperature slope tests according to different test purposes. If there is a flow channel reliability test, the system can be customized to support high-pressure liquid testing under the premise that the corresponding temperature and flow are met. At the same time, the system can be customized to meet variable pressure tests and variable flow tests (the mixed heat liquid characteristic area supports external pressure priority or flow priority functions).

The temperature of the liquid cooler must be linear and must not be lower than the national standard temperature deviation range of ±2°C under any working condition.

For liquid coolers, our company can accurately control the temperature within ±0.1℃ at specific points or the entire system. The liquid cooler must meet the basic operating conditions of the tested part below the design pressure (except for the flow channel reliable pressure test project) in terms of pressure processing, and at the same time have pressure warning and pressure alarm functions to prevent damage to the tested part. (The default operating pressure of our standard test system is 4Bar).

The flow processing of the hydraulic energy system must meet the basic conditions for the design flow operation of the tested device.

Components of Temperature Tester

The complete system includes the following functional modules:

Refrigeration system

Thermal Energy System

Liquid supply system

Central control system and protection device

Application scenarios

Mainly used in the following fields in electric vehicle testing:

Liquid-cooled power battery and its management system: Liquid-cooled testing of power battery cells/modules/systems (battery packs), battery management systems, and heat sink design and development

Micro motor: sunroof /side window/wiper

Drive motor ( MOTOR): single motor/dual motor/triple motor/quadruple motor/powertrain

Drive motor controller (MCU): Passenger car MCU/commercial vehicle MCU

Charging pile: AC charging pile /DC charging pile/charging interface/charging cable

Vehicle: OBC/DCDC

Assembly series

1. Constant temperature series → {High and low temperature series -40℃ ~+85 ℃ ethylene glycol}

{High and low temperature series -40℃ ~+130 ℃ heat transfer oil}

2. Linear series → {High and low temperature series -40℃~+85℃ ethylene glycol}

{High and low temperature series -40℃~+130℃ heat transfer oil}